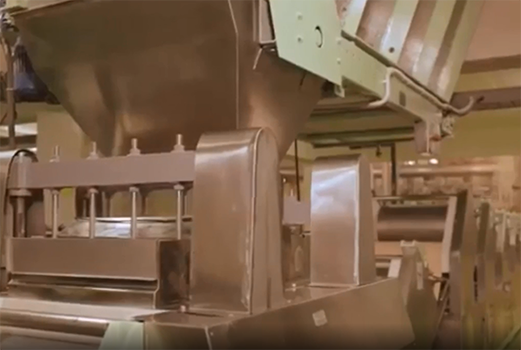

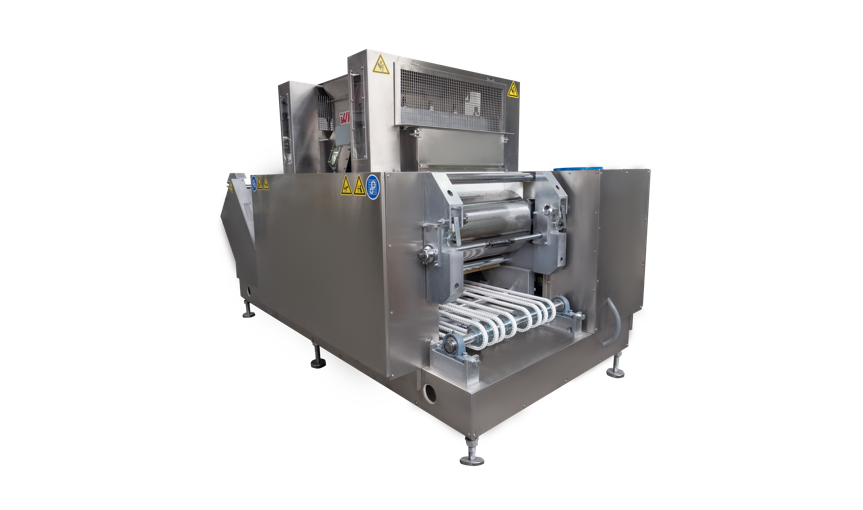

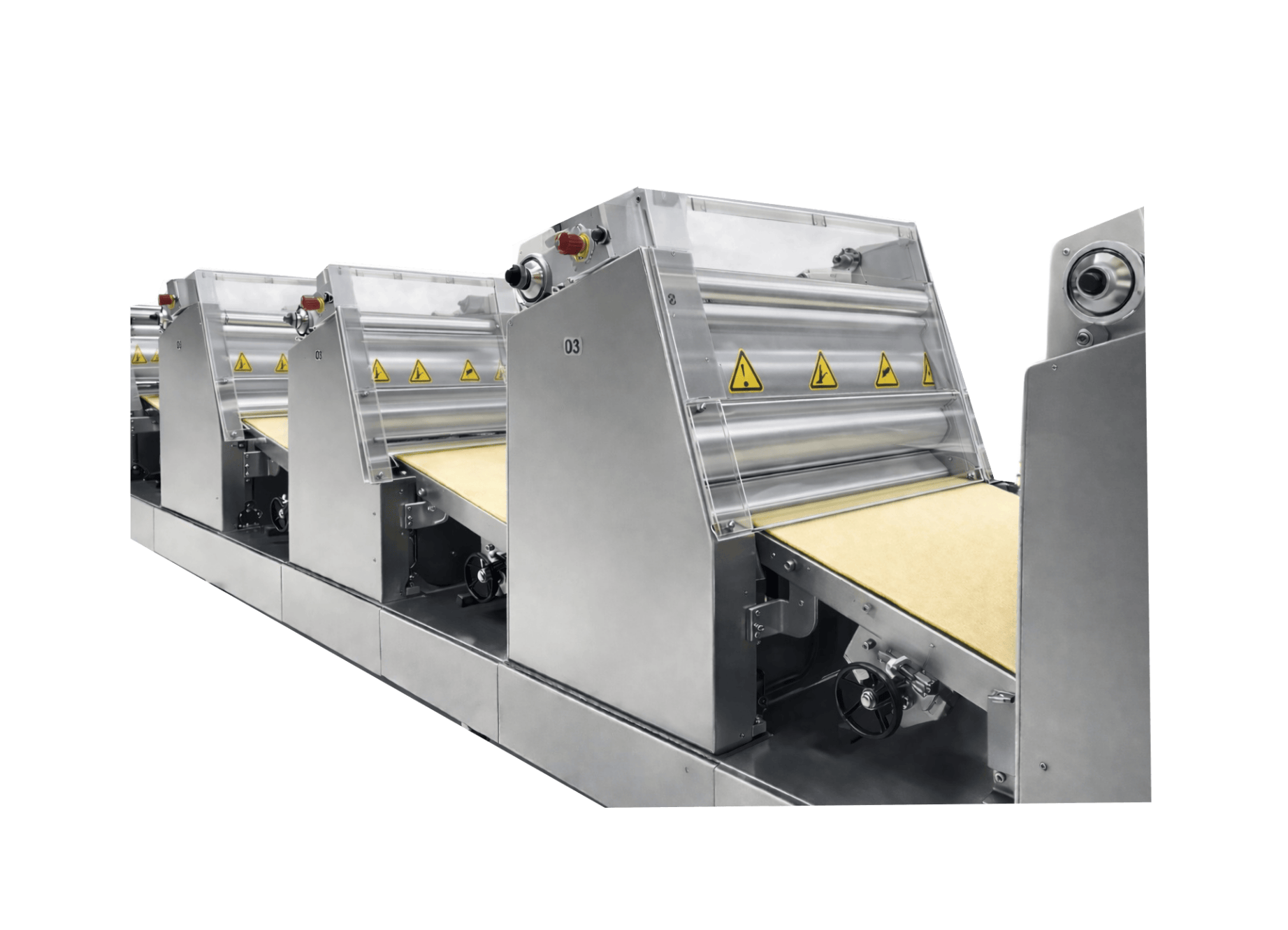

02 Dough Auto-Feeder

1) Max. holding capacity: approx.800 Kg (dough).

2) Dough mixed is discharged onto and transited by module chain (food grade) conveyor supported by rollers.

3) Dough is fed into downstream compress rollers automatically when called.

4) A rotary dough breaking system at the end of feeding tip helps to break down the mixed dough before entering the next roller station.

5) Including reversible motion of module chain operation for dough discharging in case of interruption and detachable side doors for easy cleaning.

6)Photo sensors for auto feeding control.

7)Duration time: approx. 15 min.

8)Materials: SS304.

9)Conveyor module chain: 0.18Kw, dough breaker: 0.75Kw.

English

English