- Home

-

Products

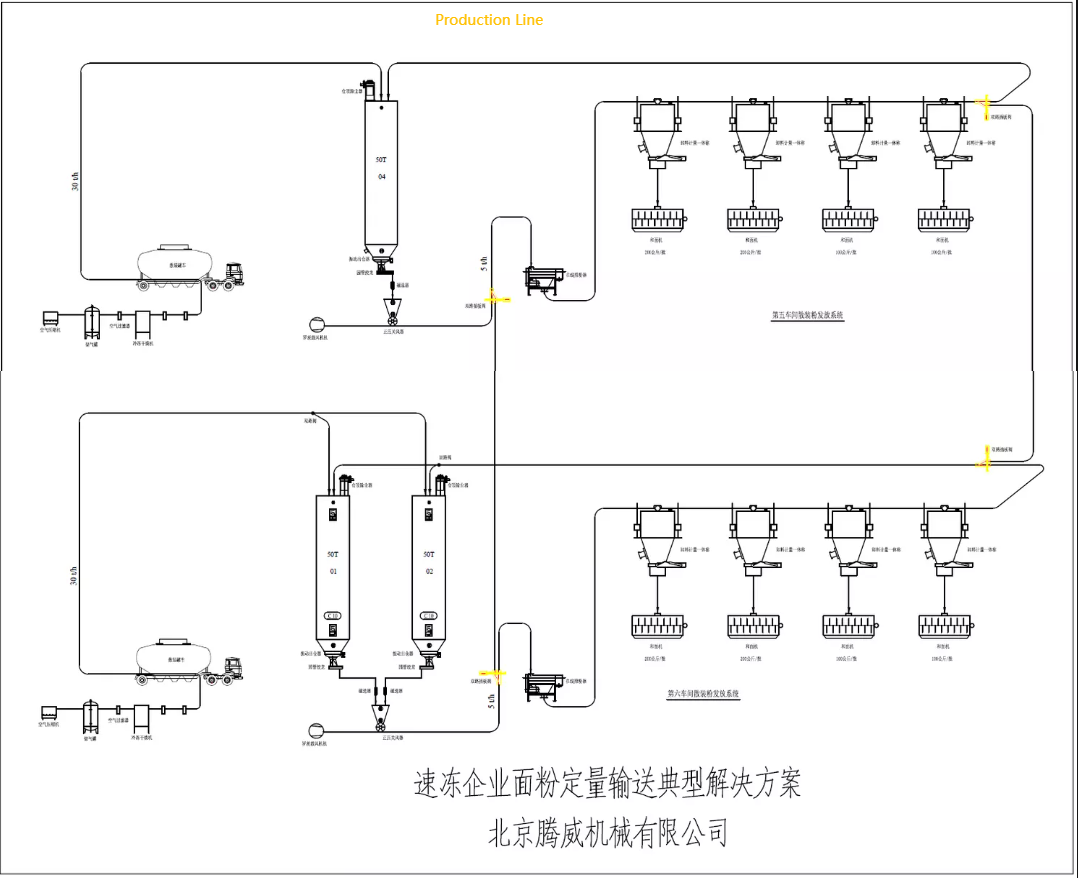

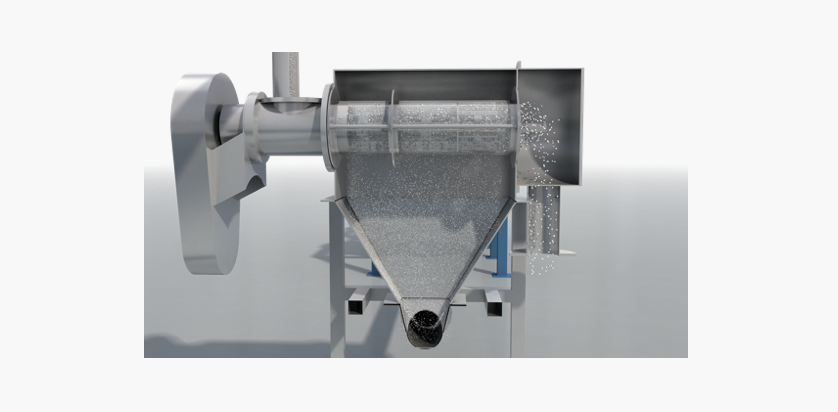

Fresh Noodle/Wrapper Production Line Air Fry Instant Noodle Production Line Oil Fry Instant Noodle Production Line Crispy Grain Snack Production Line Centralized Flour Handling and Batching System Automatic Topping Dosing and Top Application System Bread Liquid Fermentation System Fortune Cookie Production Line Packaging System

- Service

- R&D

- News

English

English