Your future is bright—enjoy the journey one cookie at a time.

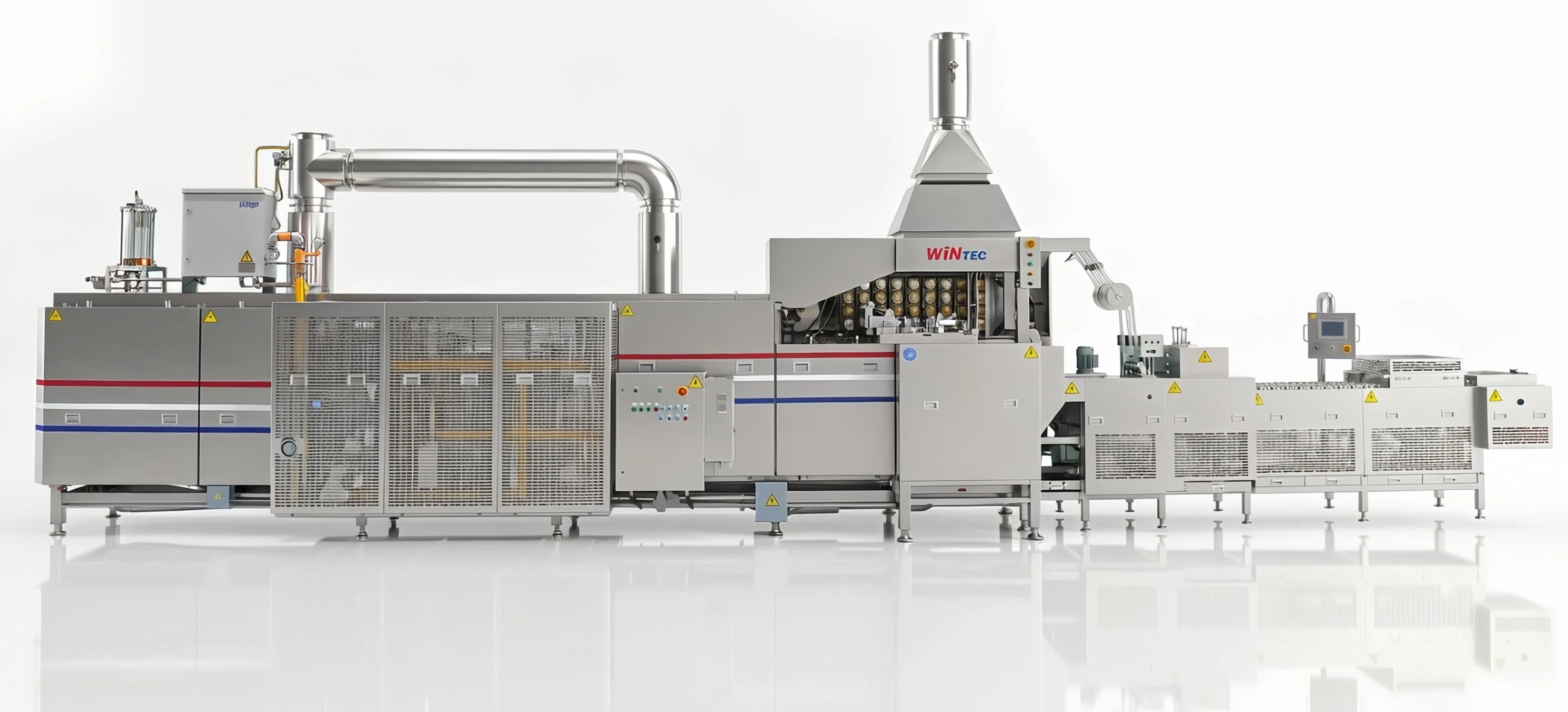

March 30th, 2005, “Power Ball”,a lottery company which is supported by 6 state government, her winning results has made a historic record, 110 people won a 2nd prize at the same time. The supporter, Multi-State Lottery Association (MUSL) is shocked of this lottery and doubt that someone has cheated. So they investigate the causes day and night. To their astonishment, most of the 110 lucky people were used lucky number from fortune cookies, and it brings them lucky. This machine, was made by Wintec Machinery Ltd Co.,

English

English